Mercedes aluminum repair requires specialized techniques using OEM-specific adhesives for superior bonding strength, corrosion resistance, and aesthetic harmony. This meticulous process involves inspection, surface treatment with aluminum primer, careful adhesive application guided by manufacturer guidelines, and final touches for a factory-like finish, ensuring structural integrity and customer satisfaction.

Mercedes aluminum repair is a specialized process that requires precise techniques and materials. In this article, we explore the significance of using Mercedes-specific structural adhesives for efficient repairs. Understanding the unique body structure of Mercedes vehicles is key to successful aluminum repair. We delve into the benefits of these specialized adhesives and provide a step-by-step guide to ensure high-quality, durable repairs that maintain the integrity and original appearance of Mercedes cars.

- Understanding Mercedes Aluminum Body Structure

- Benefits of Using Mercedes-Specific Adhesives

- Step-by-Step Guide to Efficient Aluminum Repair

Understanding Mercedes Aluminum Body Structure

Mercedes vehicles are renowned for their sleek, sophisticated design and advanced engineering, and this extends to their aluminum body structures. Understanding the unique characteristics of Mercedes aluminum repair is crucial for both original equipment manufacturers (OEMs) and specialized automotive collision repair shops. The brand employs specific types of adhesives tailored for its lightweight, yet robust aluminum panels, ensuring structural integrity and long-lasting performance.

These specialized structural adhesives play a vital role in securing body components during the manufacturing process and in automotive collision repair. They provide superior bonding strength, resistance to corrosion, and dimensional stability, which are essential for maintaining the vehicle’s safety and aesthetic appeal. By utilizing Mercedes-specific adhesives, repair technicians can effectively restore the original precision and quality of the aluminum body, ensuring a seamless fit and finish that meets the high standards expected from the Mercedes-Benz brand in both structural integrity and visual harmony during mercedes benz collision repair or automotive collision repair processes.

Benefits of Using Mercedes-Specific Adhesives

Using Mercedes-specific structural adhesives for aluminum repair offers several advantages when it comes to maintaining the integrity and original quality of a Mercedes Benz vehicle. These specialized adhesives are designed with the unique requirements of Mercedes cars in mind, ensuring precise bonding between aluminum panels. This is particularly crucial for preserving the sleek and sophisticated look that Mercedes owners expect from their vehicles.

Moreover, mercedes benz repair professionals can benefit from improved efficiency and reduced work time when using these advanced adhesives. They provide superior strength and durability, allowing for more intricate repairs while maintaining structural integrity. As a result, body shop services specializing in Mercedes aluminum repair can deliver high-quality, long-lasting solutions to their clients, enhancing customer satisfaction in the process.

Step-by-Step Guide to Efficient Aluminum Repair

Repairing Mercedes aluminum requires a meticulous approach and specialized tools, especially when aiming for efficiency. Here’s a step-by-step guide tailored for Mercedes owners seeking to restore their vehicles’ sleek aluminum panels:

1. Safety First: Ensure your workspace is well-lit and organized, with all necessary safety gear in place. Put on protective gloves, glasses, and consider ear protection before beginning. This prevents accidents during the repair process.

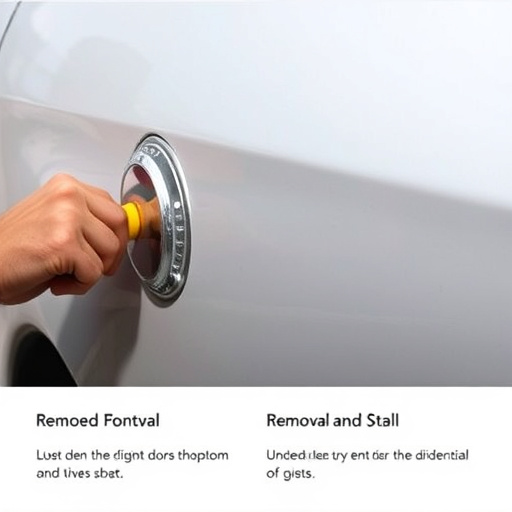

2. Inspect and Prepare: Thoroughly inspect the damaged area. Remove any loose debris or contaminated material. Lightly sand the surface to create a clean, rough texture that promotes adhesive bonding.

3. Surface Treatment: Apply a suitable primer designed for aluminum to prepare the panel for bonding. This step is crucial for ensuring long-lasting adhesion of Mercedes-specific structural adhesives. Allow the primer to dry completely according to the manufacturer’s instructions.

4. Adhesive Selection: Choose a high-quality, Mercedes-approved structural adhesive formulated for aluminum repairs. These adhesives offer superior strength and durability, ensuring your repair stands up to the rigors of daily driving. Follow the manufacturer’s guidelines for mixing and application.

5. Application: Using a precision tool or applicator, carefully apply the adhesive along the damaged area’s edges and surfaces. Ensure complete coverage without overloading the panel. Work quickly but methodically to maintain bond strength.

6. Drying and Curing: Allow the adhesive to cure according to the manufacturer’s recommended time frame. Proper curing ensures robust bonding. Some adhesives may require heat application or a specific environmental condition for optimal curing.

7. Final Touches: After the adhesive has fully cured, carefully inspect the repair. If necessary, lightly sand and re-primer any visible seams or edges for a seamless finish. Apply a final coat of paint to match your Mercedes’ original color, ensuring a factory-like appearance.

Mercedes aluminum repair requires specialized knowledge and materials. By understanding the unique Mercedes-specific structural adhesives, repairs can be efficiently and effectively carried out, preserving the integrity and original quality of Mercedes vehicles. Using the right adhesive is a crucial step in any aluminum repair process, ensuring long-lasting results for these high-performance automobiles.